Posted On

Posted On

Why should you choose 3D printing technologies

Posted On

Posted On

3D printing, also known as additive manufacturing, has revolutionized the way we approach product development, manufacturing, and innovation. This transformative technology has opened up a world of possibilities, allowing individuals and businesses to bring their ideas to life in a more efficient, cost-effective, and customizable manner. As 3D printing continues to evolve and become more accessible, it is essential to understand the key reasons why this best 3D printing technology should be a consideration for your next project.

1. Rapid Prototyping

One of the primary advantages of 3D printing is its ability to facilitate rapid prototyping. By using 3D printing, you can quickly and easily create physical models or prototypes of your designs, allowing you to test and iterate on your ideas before committing to a final product. This not only saves time and resources but also enables you to identify and address potential issues early in the development process, leading to a more successful final product.

2. Customization and Personalization

3D printing excels at enabling customization and personalization, as it allows for the creation of unique, one-of-a-kind products. Whether it’s custom-fit medical devices, personalized jewelry, or bespoke home decor, 3D printing empowers you to tailor your products to the specific needs and preferences of your customers. This level of personalization can be a significant competitive advantage, helping you stand out in a crowded market.

3. Complex Geometries

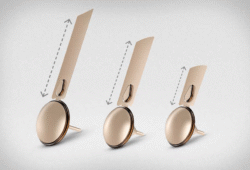

Traditional manufacturing methods often struggle to produce parts with complex geometries, but 3D printing thrives in this area. This is because 3D printing uses additive manufacturing techniques, where material is added layer by layer to create the desired shape. This allows for the creation of intricate, organic, and highly detailed designs that would be challenging or even impossible to produce using conventional manufacturing processes.

One of the key advantages of 3D printing is its ability to produce complex geometries that would be difficult or impossible to create using traditional methods. This includes designs with intricate details, organic shapes, and highly detailed features. By using 3D printing, designers and engineers can create products that were previously unattainable, opening up new possibilities for innovation and creativity.

The ability to produce complex geometries using 3D printing has significant implications for various industries, including aerospace, automotive, and medical device manufacturing. It allows for the creation of parts with unique shapes and features that can improve performance, reduce weight, and enhance functionality. This, in turn, can lead to the development of innovative products that can change the way we live and work.

4. Cost-Effective Small-Scale Production

While 3D printing may not be the most cost-effective option for large-scale production, it excels at small-scale and on-demand manufacturing. By eliminating the need for expensive tooling and setup costs, 3D printing can be a more economical choice for producing small batches or customized products. This makes it an attractive option for startups, small businesses, and individuals looking to bring their ideas to market without the burden of high upfront costs.

5. Reduced Material Waste

Traditional manufacturing methods often generate significant amounts of waste, as excess material is removed from a larger block or sheet. This subtractive process can result in a substantial amount of material being discarded, which can be both environmentally and economically costly.

In contrast, 3D printing by the biggest 3D printing companies is an additive process, where material is only deposited where it is needed to create the desired object. This approach is inherently more efficient, as it eliminates the need to remove excess material. Instead, the 3D printer precisely deposits the required amount of material, layer by layer, to build the final product.

The efficient use of resources in 3D printing leads to a significant reduction in material waste. By only using the necessary amount of material, 3D printing minimizes the environmental impact of manufacturing and contributes to a more sustainable approach. This not only benefits the environment but can also lead to cost savings for businesses, as they no longer have to account for the disposal or recycling of excess material. As sustainability becomes an increasingly important consideration in manufacturing, the waste-reducing capabilities of 3D printing make it an attractive option for companies looking to reduce their environmental footprint.

6. Distributed Manufacturing

3D printing enables distributed manufacturing, where products can be produced closer to the end-user, reducing the need for centralized production and long-distance transportation. This can lead to faster delivery times, lower shipping costs, and a reduced environmental impact. Additionally, distributed manufacturing allows for greater flexibility and responsiveness to local market demands.

7. Increased Design Freedom

The versatility of 3D printing allows for increased design freedom, as designers and engineers are no longer constrained by the limitations of traditional manufacturing processes. This opens up new avenues for innovation, enabling the creation of complex, organic, and highly customized designs that were previously unattainable.

8. Rapid Iteration and Agile Development

The speed and flexibility of a 3D architect home designer make it an ideal tool for rapid iteration and agile product development. By quickly producing physical prototypes, you can gather feedback, test new ideas, and make iterative improvements to your designs, allowing you to respond to market demands and stay ahead of the competition.

9. Accessibility and Democratization

As 3D printing technology continues to advance and become more affordable, it is becoming increasingly accessible to individuals, small businesses, and hobbyists. This democratization of manufacturing empowers people to bring their ideas to life, fostering innovation and creativity at a grassroots level.

10. Potential for Disruptive Innovation

The disruptive nature of 3D printing has the potential to transform entire industries, as it challenges traditional manufacturing paradigms and opens up new avenues for innovation. By embracing this technology, businesses and individuals can position themselves at the forefront of their respective fields, driving progress and shaping the future of manufacturing.

In conclusion, the compelling reasons to choose 3D printing technologies are numerous and compelling. From rapid prototyping and customization to cost-effective small-scale production and increased design freedom, 3D printing offers a wealth of benefits that can help you stay competitive, drive innovation, and bring your ideas to life. As this technology continues to evolve and become more accessible, it is clear that 3D printing will play an increasingly vital role in shaping the future of manufacturing and product development.